Accessory

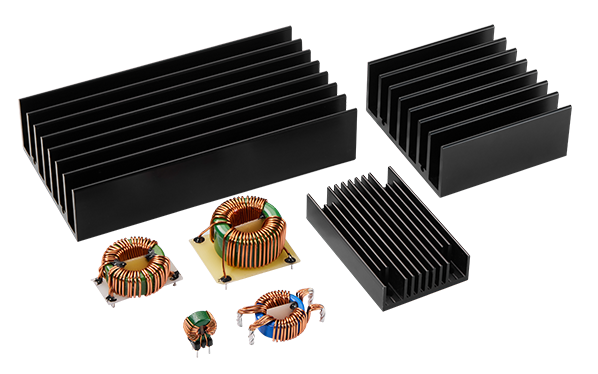

Cincon provides various accessories including heatsinks and magnetic components (common mode chocks).

Heatsink Features:

Constructed of aluminum AL6063 for optimum heat transfer

Designed specifically for DC/DC Converters and other baseplate packages

Finished with black anodize plating

Mounting hardware and thermal pad are available

| Item | MODEL NUMBER | SUITABLE DC/DC PACKAGE |

FIN STYLE | HEATSINK HEIGHT (mm) |

THERMAL RESISTANCE (C/W) | ||||||

| HEATSINK | THERMAL PAD |

MOUNTING HARDWARE (NOTES 5) |

NATURAL CONVECTION |

100 LFM | 200 LFM | 300 LFM | 400 LFM | ||||

| 1 | SBC100 (K-C087) |

N/A ^7 | CLIP HC01 | SB 1”x1” | Cross Cut | 10.0 | 12.5 | -- | -- | -- | -- |

| 2 | BC100 (K-C088) |

N/A ^7 | CLIP HC01 | B 2”x1” | Cross Cut | 10.0 | 10.2 | -- | -- | -- | -- |

| 3 | BL150G (M-C1677) |

PB01 | Soldered on PCB | Longitudinal | 15 | 5.62 | 4.94 | 3.52 | 3.14 | 2.38 | |

| 4 | LBT127 (M-C655) |

PL01 | K258W | LB 2.05”x1.2” | Transverse | 12.7 | 8.99 | 3.29 | 2.73 | 2.40 | 2.10 |

| 5 | EBL150G (M-C1819) |

PE01 | Soldered on PCB |

Eighth Brick | Longitudinal | 15 | 4.96 | 3.85 | 2.94 | 2.44 | 2.06 |

| 6 | QBL127 (M-C448) |

PQ01 | K308W or K310W |

Quarter Brick | Longitudinal | 12.7 | 5.61 | 4.01 | 3.39 | 2.86 | 2.49 |

| 7 | QBT210 (M-C421) |

Transverse | 21 | 4.78 | 2.44 | 2.06 | 1.76 | 1.58 | |||

| 8 | HBL210 (M-C308) |

PH01 | K308W or K310W |

Half Brick | Longitudinal | 21 | 3.9 | 1.74 | 1.33 | 1.12 | 0.97 |

| 9 | HBT127 (M-C091) |

Transverse | 12.7 | 4.7 | 2.89 | 2.3 | 1.88 | 1.59 | |||

| 10 | HBT254 (M-C092) |

Transverse | 25.4 | 3.0 | 1.44 | 1.17 | 1.04 | 0.95 | |||

| 11 | FBL254 (M-B012) |

PF01 | K320N | Full Brick | Longitudinal | 25.4 | 2.4 | 1.76 | 1.17 | 1.0 | 0.83 |

| 12 | FBL127 (M-B011) |

PF01 | K320N | Full Brick | Longitudinal | 12.7 | 2.7 | 2.41 | 1.59 | 1.29 | 1.07 |

| 13 | CMLH01 (M-C1618) |

PF01 | K408W | Quarter Brick-CMFD | Longitudinal | 25.4 | 2.5 | -- | -- | -- | -- |

| 14 | CMLH02 (M-C1618) |

PCM02 | K408W | Half Brick CMFD | Longitudinal | 25.4 | 1.2 | -- | -- | -- | -- |

| 15 | CMLH03 (M-D354) |

PCM03 | K412N | Full Brick CMFD | Longitudinal | 31 | 0.68 | -- | -- | -- | -- |

- With threaded mounting hole

- Example Part Numbers:

- QBL127: Quarter Brick Heatsink (12.7mm High), plate fin (longitudinal)

- FBL254PF01: Full Brick Heatsink (25.4mm High), plate fin (longitudinal) with thermal interface pad

- HBT127PH01K308W: Half Brick Heatsink (12.7mm High), plate fin (transverse) with thermal interface pad and 4 pieces of M3 x 8mm screws & spring washers

- HBL210K308W: Half Brick Heatsink (21.0mm High), plate fin (longitudinal) with 4 pieces of M3 x 8mm screws & spring washers

- Thermal data provided are for reference only. Actual cooling performance may vary by application.

- Specifcations are subject to change without notice.

- K258W: Screw set M2.5*8mm screw & lock washer x 2pcs

K308W : Screw set M3*8mm screw with spring washer x 4pcs

K310W: Screw set M3*10mm screw with spring washer x 4pcs

K320W : Screw set M3*20mm screw & spring washer x 4pcs

K320N: Screw set M3*20mm screw & lock screw nut x 4pcs

K408W: Screw set M4*8mm screw & spring washer x 4pcs

K412N: Screw set M4*12mm screw & lock screw nut x 4pcs - For volume orders, converters will be supplied with heat-sink already mounted. Separate heatsinks are only available for prototypes and small quantity orders.

- Applying proper thermal paste is recommended.

| Ordering Model Number |

Inductance |

DCR(mΩ Max) |

HI-POT (between lines) |

Rated current (A) |

Applied Series | ||

| mH | tolerance | Tested | |||||

| CMK-01 | 3.9 | ±30% | 1kHz, 0.25V | 20 | 600VAC, 3sec |

9.4 |

|

|

CMK-02 |

4.2 |

±25% |

1kHz, 0.25V |

32 |

600VAC, 3sec |

5 |

|

|

CMK-03 |

1.5 |

±33% |

100kHz, 0.25V |

9.5 |

600VAC, 3sec |

9.4 |

|

|

CMK-04 |

1.7 |

±30% |

10kHz, 0.25V |

41 |

600VAC, 3sec |

3.2 |

|

|

CMK-05 |

0.72 |

±30% |

10kHz, 0.25V |

7 |

600VAC, 3sec |

20 |

|

|

CMK-06 |

0.52 |

±35% |

10kHz, 0.25V |

1.5 |

600VAC, 3sec |

30 |

CHB200W12-72SXX |

| CMK-07 | 0.12 | ±30% | 10kHz, 0.25V | 0.7 | 600VAC, 3sec | 45 | CHB150W12-72SXX CHB200W12-72SXX |

Electrical specifications at 25℃